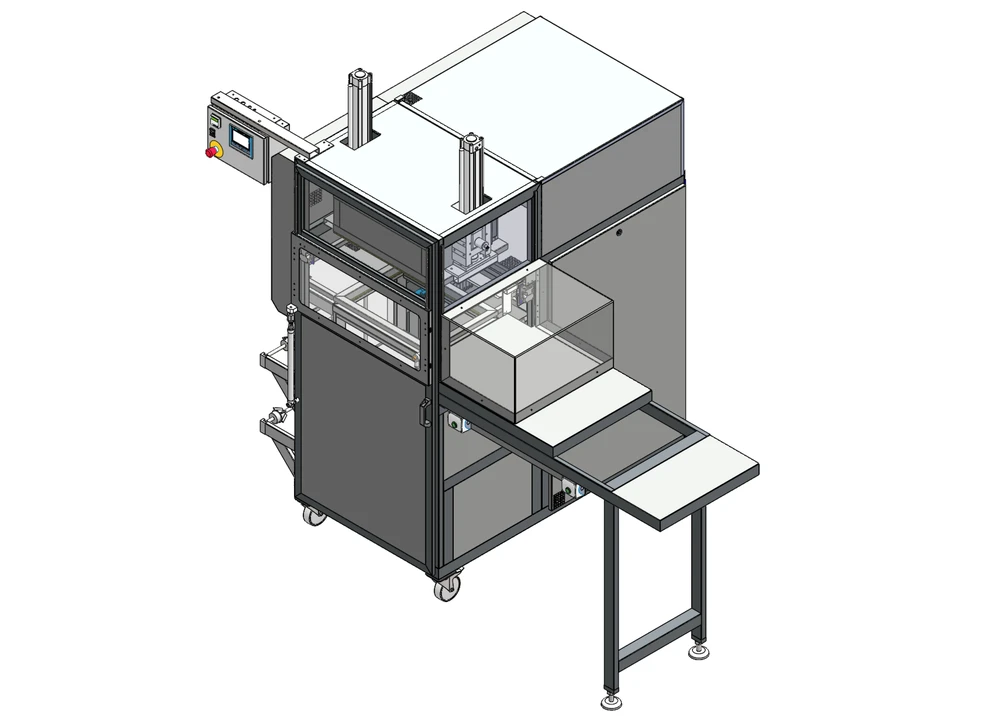

The Simple and Safe Use of Thermoforming Machines from Zappe Packaging Technology

The exact process for the production of thermoformed parts depends on which vacuum thermoforming machine you choose.

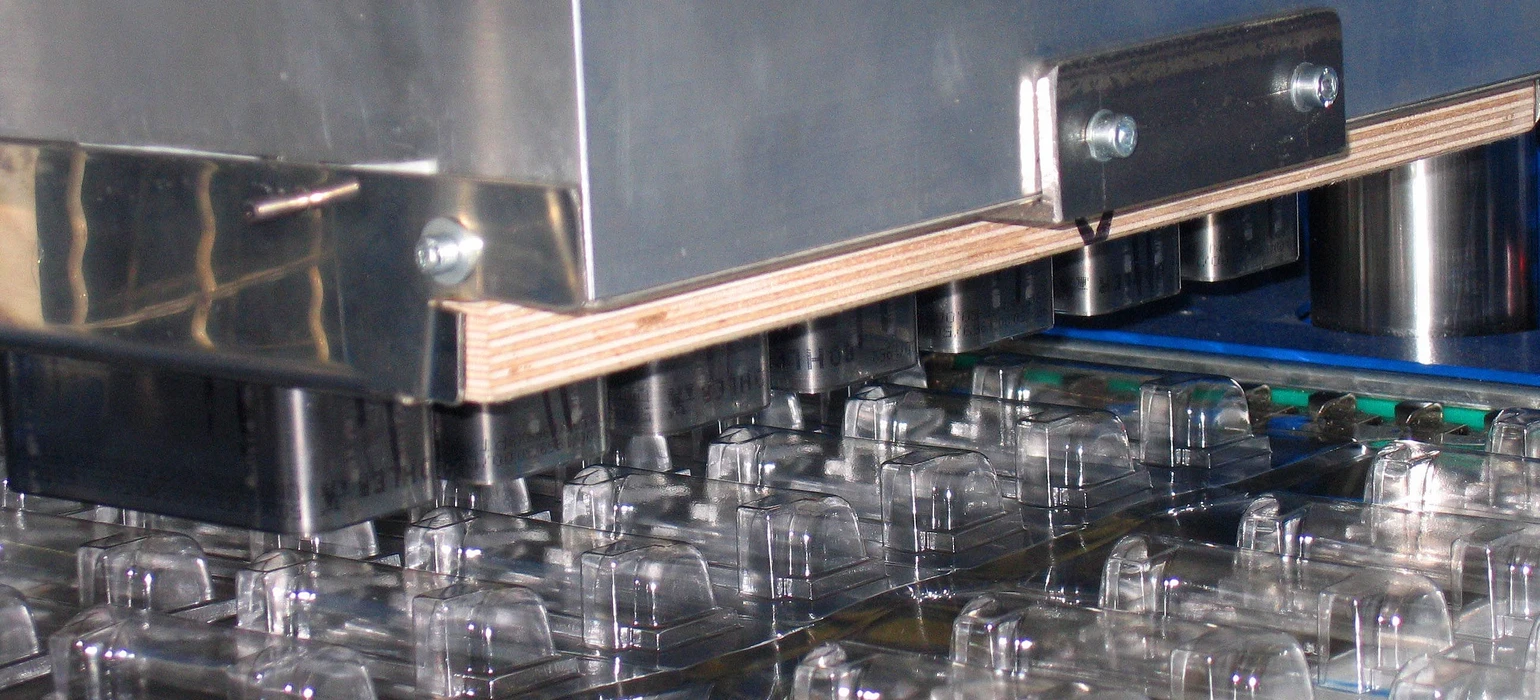

With the Zappe vacuum forming machine Base, there is a thermoforming tool located on the moulding table with the corresponding shapes of the desired vacuum-moulded parts.The heating screen moves, pneumatically controlled, over the thermoforming film or plastic sheets (e.g. ABS, PVC, PS, PET, PC etc.) on the moulding table and heats up the film.

Once the forming temperature has been reached, the vacuum table moves with the thermoforming tool into the plastic film.The vacuum pump evacuates the air so that the plastic film covers the thermoforming mould like a second skin. The vacuum duration is continuously adjustable in order to to produce thermoformed parts of different heights optimally.

If necessary, compressed air can be used to pre-stretch with compressed air to stretch the film material evenly and support the deformation process. The pre-blowing time and the amount of air blown in is adjustable.

Finally, the clamping frame opens automatically and the thermoformed product can be removed manually. The clamping frame is closed pneumatically.