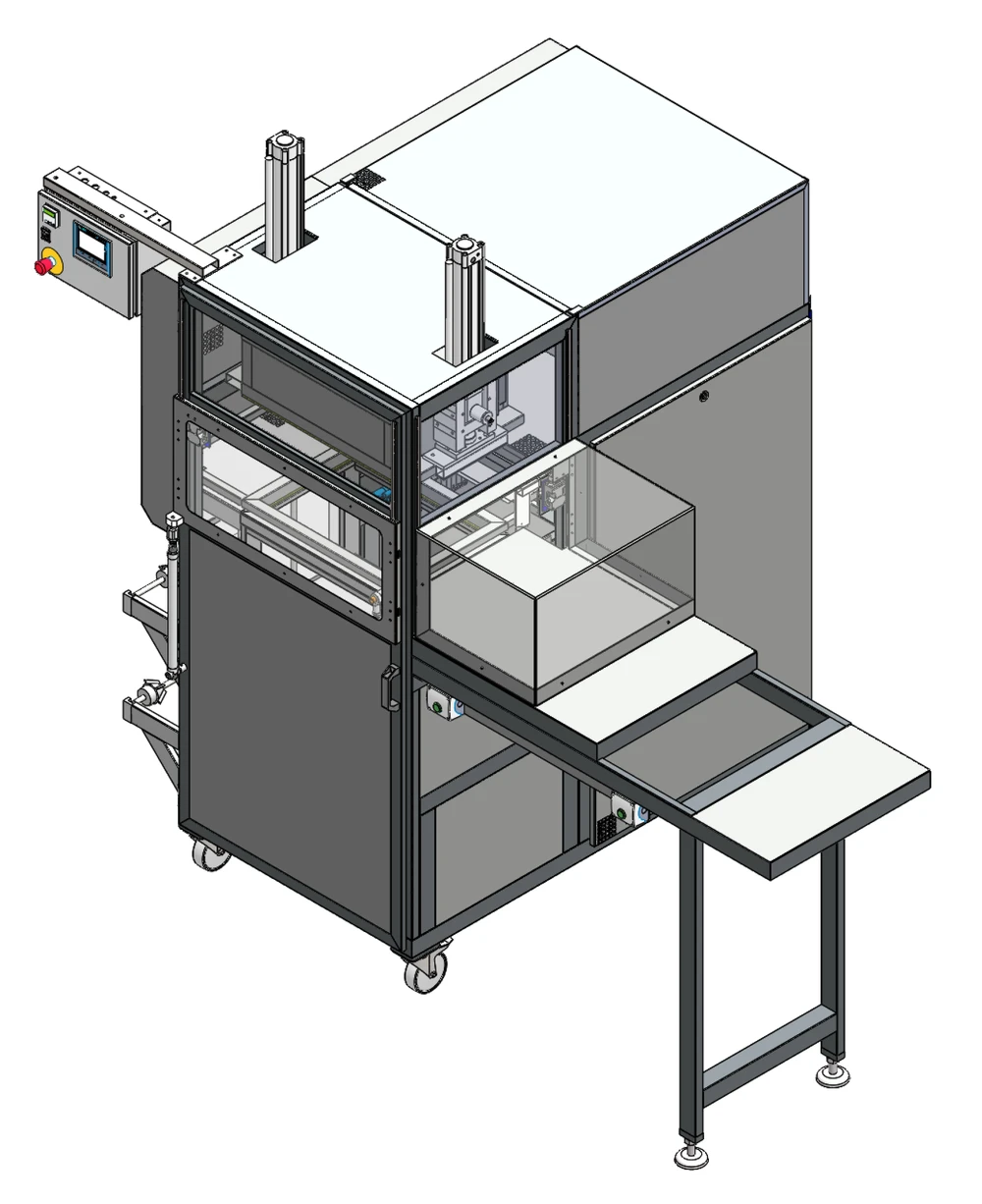

Skin Machines Directly from the Manufacturer

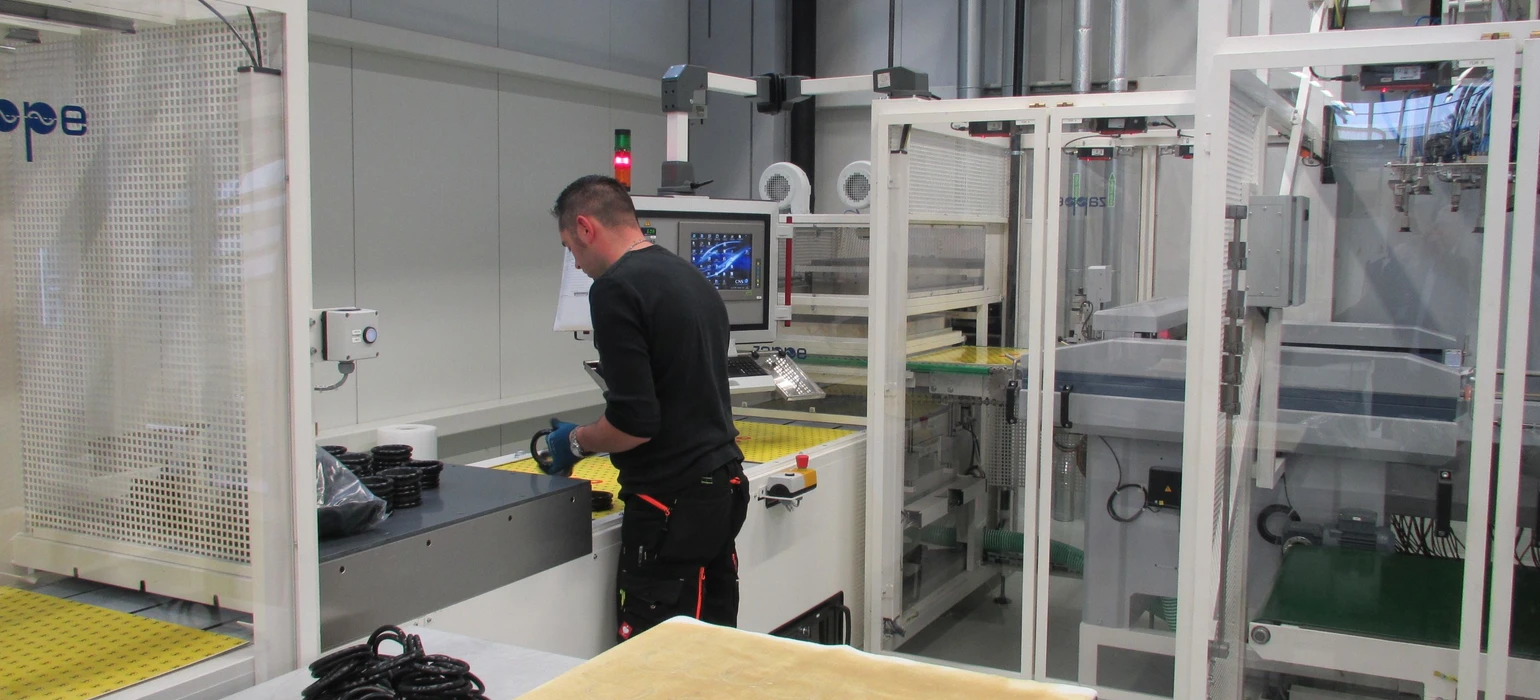

Skin machines directly from the manufacturer - This is how your Zappe skinf packer works. The skin cardboard lying on the loading table is loaded with the products to be packed and then pushed onto the vacuum table. To support your sales, you can have your company logo, advertising and information on one or both sides of the cardboard (e.g. your company logo in scatter print, product descriptions, etc.).

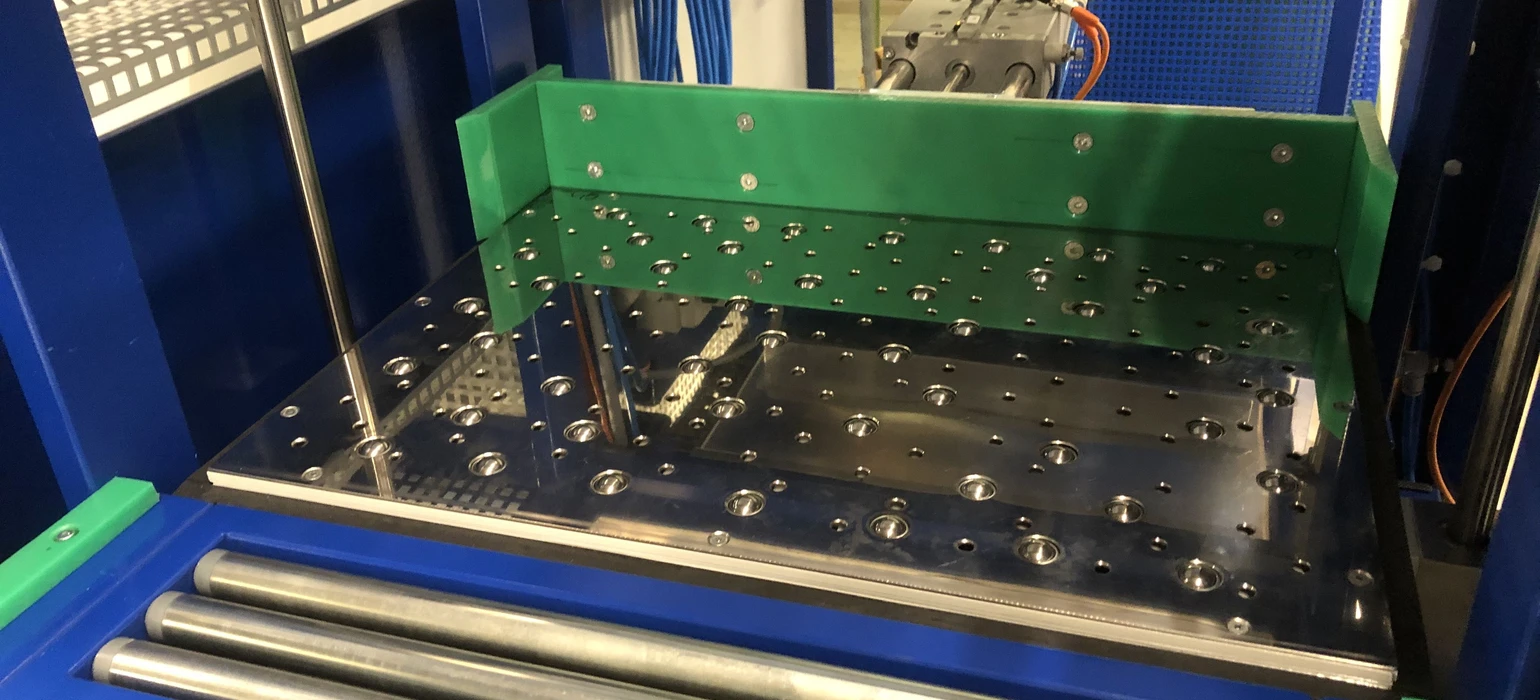

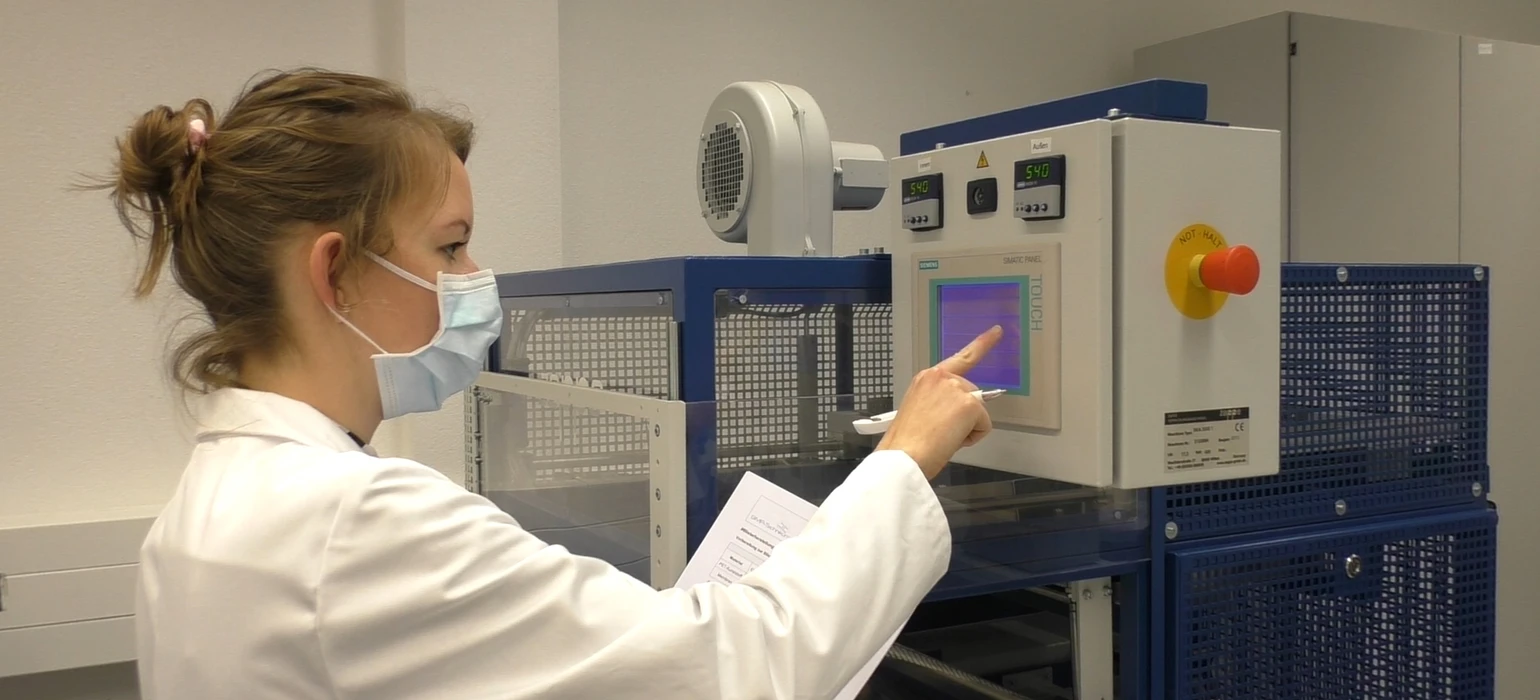

Even in the basic model, the Plexiglas safety door closes automatically, which triggers the packaging process: pneumatically controlled, the heating screen runs over the film until it is like a skin.

After the continuously adjustable heating time has elapsed, the vacuum table moves up, the heating screen returns, whereupon the built-in vacuum pump evacuates the air, so that the skin film wraps around your product like a second skin.

After the continuously adjustable heating time has elapsed, the vacuum table moves up, the heating screen returns, whereupon the built-in vacuum pump evacuates the air, so that the skin film wraps around your product like a second skin.

After this, the clamping frame opensautomatically and the finished skin pack can be removed.