From the Table-top to the Semi-automatic Film Sealing Machine

The packaging process is quick and easy to carry out. An employee places the goods in the semi-tubular film, the sealing bar is closed and the goods are sealed all around.

In the next step, the packed goods are either removed by hand or automatically transported away and collected. If required, the packed items are transported into a hot-air tunnel for shrinking.

We will quickly find out together which version and which degree of automation is the right one for your requirements: the manual table-top unit or the semi-automatic L-sealer.

Which film sealing device is best suited for your packaging tasks? Is the economical table-top version already enough for you?

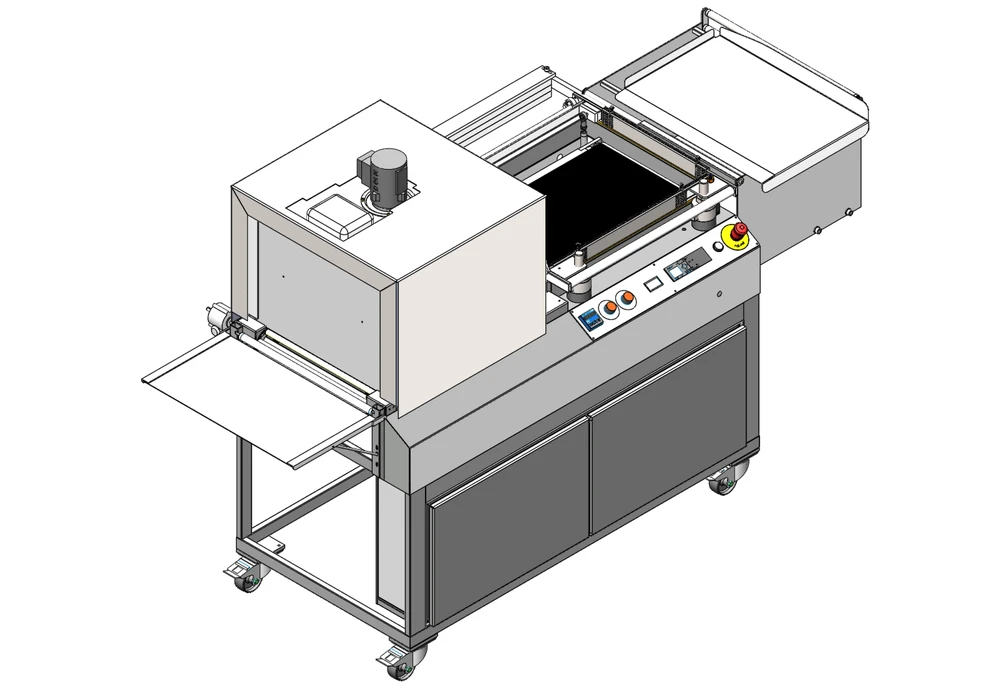

Then take a closer look at the entry-level L-sealer model here. Or do you prefer to entrust your packaging tasks to the proven Zappe Basic model? The semi-automatic film sealing machine Basis also combinable as a semi-automatic L-sealer with shrink tunnel.

The semi-automatic film sealing machine Basis is a mobile L-sealer that stands on lockable castors. The height of the sealing table can be adjusted several times in order to optimally adapt the machine to packaged goods of different heights.